Determining the expiration dates of products

The shelf life of food products is a certain period of time during which food products must retain all the organoleptic, physicochemical properties prescribed for this product.

The requirements presented must be appropriate in terms of nutritional value, as well as in the permissible content of substances of a chemical, biological nature, their compounds, and the content of microorganisms harmful to human life and health.

All requirements are presented in established regulatory documents. Requirements also apply to the compliance of indicators of functional purpose.

Requirements of regulatory documents for food product suitability criteria:

- Organoleptic properties

- Physicochemical characteristics

- The nutritional value

- Permissible content of substances of a chemical, biological nature, their compounds

- Permissible content of microorganisms dangerous to life

- Compliance with the functional purpose criteria

The shelf life of food products must be determined in accordance with the requirements.

Tax accounting

Paragraph 1 of Article 264 of the Tax Code of the Russian Federation states that other expenses for production/sales are included in the expenses that are the basis for calculating income tax. Such expenses must be economically justified (Articles 252, 265 of the Tax Code of the Russian Federation).

Recycling and destruction is the responsibility of the company in the course of whose activities a delay occurs. Therefore, corresponding expenses may reduce the income tax base. The corresponding position is contained in letters from the Ministry of Finance. For example, it is in letter No. 03-03-06/1/30409 dated May 26, 2021.

That is, the accountant can take advantage of the VAT deduction associated with examination/disposal services.

IMPORTANT! Accounting for expenses on written-off materials is performed only when the entire write-off procedure has been correctly completed. Every stage is documented. Based on the primary data, accounting entries are made.

Establishing expiration dates for products

The shelf life of food products is determined by a certain time interval: from the date of manufacture to the critical date. During this time interval, the product is considered fit for consumption.

The date of manufacture is considered to be the date of completion of the manufacturing process. The shelf life time interval consists inclusive of storage at the manufacturer's warehouse, transportation time, storage time in stores and after purchase.

The label on which the expiration date of the product is written must include the following items:

- For particularly perishable food products and products for dietary and baby food: hour, day month, year

- For perishable products: day, month, year

- For regular products: month, year

- Storage conditions rules

- Rules of use

The expiration date of perishable products does not apply to products whose container integrity was damaged during sales, transportation or at the time of consumption. The expiration date indicated on the label of a product whose storage conditions were not met also does not apply.

The shelf life of products subject to packaging is determined from the date of manufacture of the products, and not from the date of packaging.

15.3.1. Direct determination of shelf life

Despite the importance of determining the degree of safety of a food product, its HACCP analysis, that is, risk analysis, is usually carried out in parallel with determining the shelf life. As noted earlier, when studying the shelf life, it is necessary to know the quality indicators of the product and have a sufficient understanding of the mechanisms of their deterioration during storage. Therefore, determining the shelf life includes conducting experimental testing of the process of spoilage of a food product, ending with finding the point in time corresponding to the end of its shelf life. In the EU and in the UK, according to the EU Food Hygiene Directive (93/43/EEC), risk analysis is mandatory. HACCP analysis, that is, a risk analysis carried out in parallel with a shelf life study, ensures that any changes in formulation, processing conditions, packaging, etc., especially during product modification, do not compromise the safety of the product.

The most common and direct way to determine shelf life is to test the storage of the product under controlled conditions that simulate the actual conditions of the product's warehousing, transportation and distribution, but full and comprehensive testing of shelf life is very rarely possible, since it is very difficult to reproduce the conditions of transportation and storage in retail trade. The handling of the product by consumers is often unpredictable, so that the manufacturer has virtually no ability to control it. For example, in the UK, consumer handling of chilled food products, many of which are perishable, has been found to be the most variable part of the cold chain, making it very difficult or virtually impossible to simulate when testing their shelf life [9]. For this reason, most food manufacturers can only test shelf life under fixed conditions, which do not accurately simulate marketing conditions. The statement about the need to conduct research in extreme conditions that simulate consumer misuse of a product is very controversial - by its nature it is unpredictable and theoretically can give an infinite number of options.

From all of the above, it is clear that shelf life testing is nothing more than a controlled experiment that cannot be planned for all occasions. In addition, if consumer handling of a product differs significantly from that recommended (either accidentally or intentionally), any food product, regardless of whether it is perishable or highly perishable, is unlikely to remain fit for consumption throughout the entire storage period.

Temperature conditions that are commonly used when testing shelf life include:

- freezing: -18°C or lower (relative humidity usually close to 100%);

- cooling: from 0 to +5°C, maximum +8°C (relative humidity is usually very high);

- normal conditions: 25°C, relative humidity 75%;

- tropical conditions: 38°C, relative humidity 90% [26].

For given storage conditions, the following testing options should ideally be available, which will certainly require additional resources:

- optimal conditions; storage aims to obtain optimistic shelf life data, which is used to maintain the longest actual shelf life;

- typical (average) conditions; these are the most likely conditions in which the product may find itself, and storage is aimed at obtaining data applicable in real production to establish a shelf life that is acceptable for both the manufacturer and the consumer;

- unfavourable conditions; these are extreme conditions in which a given product may find itself, and storage under such conditions is aimed at obtaining such data on the shelf life that ensure the necessary safety of the product “with a margin” (by establishing a safe, but possibly shorter than real, period storage).

Whatever the storage conditions, the most important thing here is the purpose of testing, which must be defined precisely and clearly. For example, chilled and ready-to-eat pasta with ham salad can be sold either in disposable consumer packaging or in bulk from refrigerated display cases, where they are displayed in large open trays for several days. Considering that the same product can be sold in different ways and that it can have different target consumers, completely different experiments are required depending on the requirements for shelf life.

15.3.2. Scheme for directly determining shelf life

There are no universal schemes for experimentally determining shelf life. Several experimental algorithms are known [19], including those based on the statistical approach [11]. Each of them has its own advantages and disadvantages, they have different resources. For the main types of products, the testing frequency is:

- products with a short shelf life; For refrigerated foods with a shelf life of up to 1 week (e.g. ready meals), samples for assessment can be taken daily;

- products with an average shelf life; For products with a shelf life of up to 3 weeks (for example, for some baked goods stored at ambient temperatures), samples for evaluation can be taken on days 0, 7, 14, 19, 21 and 25.

- products with a long shelf life; For products with a shelf life of up to 1 year (for example, some breakfast cereals and shelf-stable cooked foods), samples for evaluation may be taken monthly or at 0, 1, 2, 3, 6, 12 and (possibly) 18 th month. The specific frequency of sampling depends on the type of product and the availability of information regarding its behavior during storage [26].

The problem of control samples is very important. For many foods, deep freezing and subsequent thawing do not have a significant effect on their organoleptic properties. In such cases, low temperature storage may be used to store control samples used in shelf life testing. If this method is not applicable, it must be possible to prepare fresh control samples, identical in all respects to the stored samples, at any time during the study. The presence of a sufficient number of control samples, representative of the products intended for sale, is difficult to overestimate, since the prototypes are evaluated precisely in relation to them.

15.3.3. Shelf life testing

An acceptable shelf life assumes that the product during this time retains its characteristic organoleptic, chemical, functional, microbiological and physical characteristics. Therefore, when determining the shelf life, as a rule, tests are used that are specific to a particular product and reflect its quality indicators. In practice, it should be borne in mind that not one, but several spoilage processes can operate, both in parallel and sequentially. There is always a problem of identifying all processes, including those that limit the storage period. To implement a control system designed to prevent rancidity in flour and sugar confectionery products, a systematic and structured approach is used based on the principles of HACCP [10]. This approach follows the basic principles of HACCP, and a risk factor is understood as a biological, chemical or physical indicator (condition ) food product, which can deteriorate its quality and lead to spoilage, as well as limiting the shelf life of the product. Systematic application of these principles allows us to identify CCPs in which control must be ensured. These CCPs are necessary to eliminate or mitigate the risk factor and prevent premature expiration of the shelf life. So, to determine the shelf life depending on the type of product and the mechanisms of its deterioration, the following types of tests are used (separately or in combination):

- microbiological tests, including challenge testing;

- chemical analysis;

- testing of physical indicators (measurement of rheological characteristics, study of microstructure, etc.);

- organoleptic evaluation.

In table 15.1 provides some examples of specific indicators for determining shelf life, taking into account specific spoilage mechanisms. This does not mean that all tests without exception should be used regularly and continuously, but sensory analysis, including taste assessment, is used in all studies for any standard determination of shelf life. Recommendations for conducting sensory analysis are given in various British and International Standards, in sensory reference books, and in other chapters of this book. A list of relevant standards for sensory analysis that may be of interest to the reader is given in Table. 15.2.

15.3.4. Features of using experimental data to assign shelf life

Assigning shelf life for food products is greatly simplified if appropriate standards are in place. For example, in the UK, the microbiological criteria for dairy-based products used to determine shelf life are precisely defined by the Dairy Products (Hygiene Aspects) Regulations 1995 [16]. Similarly, the Coffee and Coffee-Containing Products Regulations 1978 [14] require that “instant coffee” contain at least 95% coffee solids, i.e. no more than 5% moisture. Depending on the degree of grinding of the coffee and the packaging used, the acceptable shelf life should be within this statutory limit at the point of sale. Tin content (especially when using tin cans) may be a serious risk factor limiting shelf life. According to the Tin in Food Regulations 1992 [15], the sale of any food containing more than 200 mg/kg of tin is prohibited. In the UK during 1998-2002. There have been at least 10 recalls of products in various media outlets, including canned sliced tomatoes, spaghetti in tomato sauce and tomato soups. Thousands of cans were withdrawn from trade due to excess tin content.

In addition to standards, general recommendations are very useful in establishing final shelf life. For example, the UK Health Protection Agency has provided guidance on maintaining the microbiological quality of certain ready-to-eat foods [12], and the IFST provides useful guidance on the development and application of microbiological quality criteria [18]. One of the main criteria when determining the shelf life of breakfast cereals with vitamin supplements was the vitamin content indicated on the packaging.

Table 15.1. Test indicators for identifying different types of food spoilage

| Product | Storage conditions | Applicable tests | Approximate shelf life | Source |

| Sardines canned in sunflower oil in glass jars | 4°C | • Total content of nitrogen volatile compounds • trimethylamine content • pH • Organoleptic assessment (on a descriptive 9-point scale) | 120 days at 4°C | [13] |

| Boiled shrimp in brine with a preservative (in a package with RGS) | 0, 5, 8, 15 and 25 °C | • Challenge tests using Listeria monocytogenes and Clostridium botulinum spores • Organoleptic evaluation (smell, taste, texture and appearance on a 3-point scale) • pH • Total content of nitrogen volatile compounds • Moisture loss, % | 7 months at 0 °C, 4-5 days at 25 °C | [8] |

| Chinese sausages in vacuum packaging with various preservatives: sorbitol, sodium lactate, nisin | 20 °C | • Microbiological tests (APC, LAB, etc.) • Total content of nitrogen volatile compounds • pH • Test for dextran production • Organoleptic evaluation using a 7-point scale | 25 days at 20 °C (for sausages with sodium lactate) | [35] |

| Sauces and dressings | Normal conditions (25 °C, 75% relative humidity) | • Microbiological tests, including provocative tests • Organoleptic evaluation (color, smell, taste, texture, appearance of emulsion, etc.) • pH | Up to one year in unregulated conditions (depending on product type) | [31] |

Table 15.2. List of regulatory documents on organoleptic evaluation of food products

| British Standards (BS) | ISO Standards | Name |

| 5098:1992 | 5492 | Glossary of terms related to sensory evaluation |

| 5929-1:1986 | 6658 | Methods for organoleptic evaluation of food products. General methodology |

| 5929-2:1982 | 5495 | Methods for organoleptic evaluation of food products. Paired comparison test |

| 5929-3:1984 | 4120 | Methods for organoleptic evaluation of food products. Triangle test |

| 5929-4:1986 | 6564 | Methods for organoleptic evaluation of food products. Taste assessment methods |

| 5929-5:1988 | 8588 | Methods for organoleptic evaluation of food products. Test “A” - “not A” |

| 5929-6:1989 | 8587 | Methods for organoleptic evaluation of food products. Ranging |

| 5929-7:1992 | 3972 | Methods for organoleptic evaluation of food products. Taste Perception Research |

| 5929-8:1992 | 10399 | Methods for organoleptic evaluation of food products. Duo-trio test |

| 5929-9:1992 | 5496 | Methods for organoleptic evaluation of food products. Training tasters to detect and recognize odors |

| 5929-10:1999 | 11037 | Methods for organoleptic evaluation of food products. General principles and methods for assessing the color of food products |

| 7183:1989 | 8589 | Design of premises for organoleptic evaluation of food products |

| 7667-1:1993 | 8586-1 | Tasters for organoleptic evaluation. Selection, training and supervision of selected tasters |

In the absence of appropriate standards or recommendations, manufacturers must determine their own shelf life limits based on microbiological, chemical or organoleptic criteria. To ensure accurate and reproducible shelf life, experimental testing of shelf life must be carried out each time, and the following factors must be taken into account when interpreting the data obtained:

- degree of freshness and quality of raw materials used in experiments;

- production volumes that affect shelf life after transition to full-scale production of a given product;

- possible deviations in the quality of different batches of the product during mass production;

- sanitary and hygienic conditions in production;

- the need to use recycled raw materials.

Shelf life of dairy products

Dairy products are divided into: natural dairy products without additives and preservatives, dairy products, the packaging of which is made using a special technology - vacuum, and dairy products made with the addition of preservatives, substitutes and various additives.

Establishing the shelf life of dairy products is based on full compliance with the law and after testing in an independent laboratory.

The expiration date provides for a small reserve of shelf life for the product to be consumed after the stated expiration date, without loss of quality and safety.

Criteria on which the shelf life of dairy products depends

- Raw material quality

- Sanitary and hygienic indicators

- Process automation

- Compliance with production technology

- Type of packaging

The shelf life of dairy products is valid only with mandatory compliance with storage conditions, the transportation process, and the integrity of the packaging. The storage mode for dairy products is indicated on the packaging.

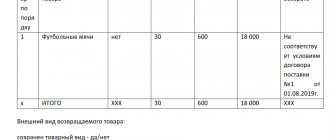

Primary documentation on overdue

The sequence of write-off activities is determined by the company itself. It is necessary to introduce all the necessary norms into local acts. In particular, this information should be included in local acts:

- The procedure for detecting and withdrawing from overdue sales.

- Procedure for sending overdue items for disposal.

- Documentation.

Detection of delay is confirmed by acts. They contain this information:

- Product name (determined on the basis of accounting nomenclature).

- Amount of delay.

- The place where the expired items were stored.

The primary report is compiled according to certain forms. TORG-15 is suitable for confirming the fact of damage. TORG-16 is suitable for confirming the withdrawal of materials from circulation.

ATTENTION! The company can develop its own forms. At the same time, it must follow the requirements prescribed in Article 9 of Federal Law No. 402 of December 6, 2011.

IMPORTANT! Recycling and destruction are different activities. Recycling does not always mean destruction. Sometimes after this the product can be used. Both destruction and disposal are carried out on the basis of an expert opinion and an order from the manager.

Shelf life of non-perishable products

Products with a long shelf life are products that, over a long period of time, without observing temperature conditions, can correspond to their consumer qualities.

Dry products retain their specified shelf life even after the packaging has been damaged.

The storage time for canned food is set from the date of completion of the technological process until the container is opened.

Non-perishable products include these products:

- Flour and dry flour products

- Sugar, salt, tea

- Dried vegetables and fruits

- Herbs, spices, vinegar

- Alcohol products

- Canned food in jars

Preservation of taste and nutritional qualities of non-perishable products is determined by correct storage conditions. Products that do not have an expiration date are not presented in the unified register of food products, indicating their expiration date.

What difficulties may you encounter if you have lost your receipt and the product you purchased is of poor quality or damaged?

What is a technically complex product and how to return it? Read about this and much more here.

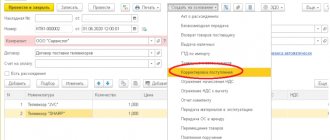

Typical write-off transactions

To better understand the principle of using a particular account, it is best to consider situations using an example.

Example

On March 31, 2021, we conducted an inventory at the central warehouse of the supermarket chain. Based on the results of the inventory, the following was revealed:

- a batch of rice cereal with an expiration date until 03/20/2021 worth 12,000 rubles;

- a batch of buckwheat with an expiration date until 04/05/2021 worth 16,000 rubles.

- Based on the expiration dates, it was decided to withdraw both batches from sale.

An entry was made in the accounting: Dt 41 / Expired goods (hereinafter referred to as ISG Goods) Kt 41 / Goods for sale

- Both goods had no external signs of damage. Therefore, samples of both cereals were sent for examination.

Expenses for expert analysis (1,770 rubles including VAT) and the cost of transferred samples were reflected in accounting:

Dt 91 Kt 76 — 1,500 rub. — examination;

Dt 19 Kt 76 - 270 rub. — VAT on examination services;

Dt 91 Kt 41 / ISG products - 100 rub. — cost of samples (a sample was taken from each product costing 50 rubles, 2 × 50 = 100).

- Based on the results of the examination, buckwheat groats were allowed to be disposed of, while rice groats were ordered to be destroyed.

3.1. A third-party organization was hired to destroy the rice grains, and they billed RUB 2,360 for their services. (including 360 rubles VAT). The accountant recorded the following entries:

Dt 94 Kt 41 / ISG products - 11,950 rub. (12,000 – 50);

Dt 91 Kt 94 — 11,950 rub. — the cost of destroyed goods is written off;

Dt 91 Kt 76 — 2,000 rub. — expenses for the services of a third-party destruction organization are taken into account;

Dt 19 Kt 76 — 360 rub. — VAT on services provided by a third party.

3.2. Buckwheat was sold to an animal shelter for 8,000 rubles. The following entries were made in accounting:

Dt 62 Kt 90 - 8,000 rub. — revenue from sales accrued;

Dt 90 Kt 68 / VAT - 1,220 rub. — VAT on sales;

Dt 90 Kt 41 / ISG products - RUB 15,950. (16,000 – 50).

Consumer and his rights

If the expiration date has not yet expired, the buyer has the right to:

- Insist on the elimination of defects in defective goods, and repair work (if possible) can be carried out by both the seller and the manufacturer.

- Return the purchased low-quality product to the store, whose employees are obliged to provide a full refund.

- Demand financial compensation from the seller or manufacturer if the repair of a low-quality product was carried out at the expense of the buyer.

- Demand a discount, the size of which should be proportional to the detected defects in the product.

- Replace the product with an analogue or product that has similar properties and consumer characteristics (if necessary, the price is recalculated).

- Return the product to the retail outlet due to its expiration date. In this case, the buyer has the right to demand a refund of the full amount of money or the provision of a similar product, but of proper quality.

What determines the storage period?

The shelf life of cosmetics is directly related to their composition and exposure to external factors. A large one will indicate a high concentration of preservatives. But this will not protect against environmental influences: temperature, humidity, sunlight.

Where is the best place to store

The best place to ensure the safety of the properties is the refrigerator. In the summer, when the temperature rises to 30 °C, the quality of the product on the shelf or chest of drawers will rapidly deteriorate. And in winter, dry air and heat from radiators contribute to deterioration.

It is acceptable to store cosmetics in the bathroom, but the balance of temperature and humidity must be maintained, or in a closed cabinet in the living room.

Where you can't

The list of places where keeping creams is undesirable and detrimental to their benefits and safety is much more extensive:

- bathroom near radiators;

- shelf, chest of drawers Direct sunlight, light, and temperature changes destroy components.

ADVICE! To minimize the introduction of bacteria from your fingers, you need to use special spatulas for applying cosmetics.

Period of use

Directly depends on the composition. Products that are stored for a long time are more profitable. But the preservatives in their composition are not very useful. For skin, the preferred option is one with natural ingredients.

Which formulations are suitable longer?

Facial and body care products with a high concentration of preservatives can enjoy long shelf life and storage. They retain their characteristics for a long time, but accumulate in the body and are harmful to the skin. Can cause allergic reactions and irritation.

Which compounds deteriorate faster?

Natural ingredients deteriorate quickly; such cosmetics sometimes need to be used several months in advance. But it is as useful as possible; negative consequences, with the exception of individual intolerance, are extremely rare. However, the cost of such a product is much higher.

Bottom line. So what's the difference?

If the product retains all the declared properties and qualities that were inherent in the new product, then this time period is understood as shelf life . After the expiration date, the product can be used without fear of causing any harm to health.

The product is considered unsuitable for use after the expiration date . You cannot equate shelf life and expiration date; this is a categorically incorrect reasoning. Thinking this way can be harmful to your health.

22 Oct 2021 Guardian 2247

- Related Posts

- Army dry rations

- Iodized salt

What happens to the cream after opening?

By removing the protective film, the consumer breaks the seal. Before this, bacteria and microbes from the external environment did not get inside, the factors acted less aggressively.

The discovery provokes free access of microorganisms to a fatty product containing nutrients - an excellent basis for reproduction. At the same time, the beneficial properties decrease with each week of the open state.

The result of the process is the complete uselessness of the cream by the end of the period and a potential threat to health after crossing this time limit. External signs will indicate decay: changes in smell, color, texture.

You need to understand that tubes with a narrow neck provide less access for microorganisms, which means the product retains its properties longer. Wide jars have the opposite effect.