5/5 (6)

What is enshrined in law

Art. 18 of the Law on the Protection of Consumer Rights states that if deficiencies are discovered in the work performed, you have the right to demand that the contractor eliminate the identified deficiencies as soon as possible and at his own expense.

Also:

- you have the right to demand a reduction in the initial cost in proportion to the identified deficiencies;

- You can eliminate the shortcomings yourself or with the involvement of third parties. Then demand reimbursement from the main contractor for the expenses spent on repairs;

- if the identified deficiencies cannot be corrected, then you can safely terminate the contract and demand that the contractor return the advance.

If the performer says that he has eliminated the shortcomings, then demand from him documentary evidence of his words. This is your right, and he is obliged to provide all the required papers.

If defects are detected in installed metal-plastic structures, in addition to the above requirements, you can set a deadline for eliminating the identified deficiencies. Naturally, the time frame should be reasonable, about 7-10 days depending on the degree of defects. And everything is according to Art. 29 and 30 of the same consumer protection law.

If the contractor was unable to eliminate the shortcomings within the time limit set by you, he will have to pay a penalty. Its size is 3% for each day of delay.

To remember. If you discover any shortcomings in the work, you must send a written complaint to the contractor, in which you must indicate all your requirements for elimination and the deadlines for this.

If the contractor ignored your demands, then feel free to sue. And don't be afraid to defend your rights.

Attention! Our qualified lawyers will assist you free of charge and around the clock on any issues. Find out more here.

Procedure in case of detection of work deficiencies

The very first thing you need to do is find the team that carried out the installation and talk to them. It is necessary to explain to them the reason for its appearance, tell them about the identified defects and state to them your requirements.

If they do not listen to your words, and all attempts to establish a constructive dialogue with them fail, then you can begin to take more decisive action.

A plastic window installed with defects is grounds for filing a complaint. But before you begin negotiations with the contractor, you need to draw up a plan for your requirements. At the same time, formulate them as clearly and clearly as possible.

After all, you don’t come to negotiations with the management of the contractor’s company with a simple angry letter that does not mention either broken fittings or deformation of slopes and frames. And there are only rare mentions of the fact that now it is blowing from the window, and they are constantly sweating. Such a complaint will not even be considered.

Are you sure that you were supplied with defective products, or that the installation was carried out in violation of the requirements? In this case, you will need to find the main flaw in the design or installation and focus your efforts on it.

According to experts, the best thing for you to do is to first become familiar with your rights and only then begin to protect them by writing a complaint. After all, the law “on the protection of consumer rights” contains all the information you need.

Deadline for responding to a written complaint under the consumer protection law.

Read how to calculate the state fee in court here.

Who should change windows in a municipal apartment, read the link:

Important! Legislation ensures that the services provided to you are safe and of high quality. You can receive from the contractor all the information about the installation, construction materials and components, and the operating features of the windows subsequently.

But the most basic point in this law is compensation for damage. After all, incorrect installation will subsequently lead to costly repairs and replacement of damaged parts.

Is it possible to save on installation?

Saving on installation is unacceptable. As you know, most homeowners who install windows strive to solve two problems:

- keep warm,

- reduce noise levels.

Improper installation of plastic windows can ruin all efforts. How to avoid this?

Correct installation of a plastic window is the key to warmth and comfort in the home

Hidden defects of plastic windows

In some cases, defects may be discovered only some time after the start of operation. Such defects are classified as hidden. Question: what should the owner do?

Art. 18 of the above-mentioned consumer protection law says that the consumer can make claims against the contractor (seller, manufacturer) regarding defects discovered in the product during the entire warranty period or expiration date.

In their work, any manufacturer of a product and its seller must follow the standards. You will also have to familiarize yourself with them.

Please note! They are as follows:

- GOST 23166-99. These are the general technical characteristics of window units;

- GOST 30674-99. PVC window blocks;

- GOST 30673-2013. PVC profiles for door and window blocks;

- GOST R 52749-2007. Window installation seams with self-expanding vapor-permeable tapes;

- GOST 30971-2012. Assembly seams of junctions of window blocks to openings in the wall;

- GOST R 54170-2010 colorless sheet glass;

- GOST 54175-2010 glued double-glazed windows.

The claim is made as follows:

- First, we indicate the contractor (seller) with his full details. Then your data – full name, address and telephone number;

- Below we describe the most significant of the detected shortcomings. At the same time, we refer to deviations from the requirements of the standards;

- express our demands (see above);

- indicate the deadline (desired) for correcting the defects;

- date and signature;

- We attach all available documents (copies). These can be receipts, cash receipts, a service agreement and various additions to it.

Incorrect installation of PVC windows in terms of wall thermal insulation

This mistake will contribute to the creation of cold bridges at the junction of the wall and window frame. In a single-layer wall, the window should be located in the middle of the wall, in a three-layer wall - in the plane of the thermal insulation, and in a two-layer wall - at the very edge in close proximity to the insulation or extend beyond it.

Carrying out an examination

An examination of the installation of PVC windows allows us to identify:

- violation during installation of the connecting unit. A normal knot is sealed in three layers. The first is to protect the window from the influence of the external environment, the second is insulation, and the third is a vapor barrier. Typically, installers who want to work faster apply only two, or even just one layer;

- The fastening of the window block is broken. According to the rules, the corners of the window must be fixed at a distance of at least 150 mm from the internal corners of the wall. This is necessary because the window material expands greatly when exposed to sunlight;

- The mounting unit is connected incorrectly. When done correctly, it is tightly connected to all parts of the structure so that cold air cannot enter the empty compartments of the window chambers. Only a tight connection allows you to fully use the property of a PVC window - thermal insulation.

Errors and their consequences

- Violation of general requirements. You may run into scammers who will install without following:

- Parameters of SNiP 2.08.01-89* “Residential buildings” for premises. Air temperature in winter and summer, humidity, and the quality of heating have almost a decisive influence on operation. It is worth remembering that only the client or the housing office can influence these parameters, installation companies have nothing to do with it. A competent surveyor can only draw the client’s attention to violations: the apartment is very cold, the hood is not working, etc.

- Requirements for materials of installation joints (according to GOST). The choice of quality materials is of paramount importance. Before installation, check compliance with the expiration date, storage conditions, permissible temperature conditions for work on mixtures, compatibility and water resistance of the materials used.

Poor installation may cause sashes to sag, glass to crack, etc.

Due to neglect of general requirements, after some time moisture will begin to accumulate in the seams of the structure, the slopes will crack, and temperature changes will cause mold to appear. And these are only the lesser of the evils, because low-quality materials can emit harmful substances that have a negative impact on the health of residents. Afterwards, it is very difficult to prove the fact of their use during installation.

- Poor installation. Amateurs often make mistakes at all stages of installation:

- Preparing the opening. It is not done or done incorrectly. This leads to peeling of the assembly seam materials from the opening and, as a result, to blowing, freezing, and a reduction in service life. Installers must carry out preliminary preparations according to the following scheme: dismantling old windows, removing remnants of frames and fasteners;

- sealing large holes and craters in the opening;

- high-quality surface dust removal;

- drying (in winter);

- moistening the surface (when working with appropriate materials);

- priming the surface of the opening.

Remains of frames and fasteners from previous structures interfere with the installation of new ones and negate the effect of foam and sealants. Dust removal, moisturizing and priming ensure reliable adhesion of surfaces, preventing drafts and ice formation on the window. Also, insufficient removal of ice and drying of the opening in winter will lead to the accumulation of moisture in the installation seams and the formation of mold, consequently reducing the service life of the foam and neutralizing its insulating properties.

- Improper installation and fixation of the window in the opening leads to the structure sagging in level. Among the typical mistakes at this stage are: the use of thin plates for drywall, instead of specialized ones. Thin mounts are not designed for such loads. The desire to save will result in additional expenses and replacement of the package in a year or two;

- non-compliance with the spacing of fastenings (5–7 points instead of 8–10) is not a critical violation, but further use of structures (especially in old buildings) is reminiscent of playing Russian roulette;

- using the wrong pads . Often, instead of dry wood or plastic, they use anything: stones, pieces of concrete, timber, rags, plastic scraps. After this, during operation, the window on such linings sags: cracks and other defects appear. There can be no question of high-quality heat, moisture and noise insulation when using the structure.

Installation requires compliance with all dimensions and proportions

- Incorrect provision of the assembly seam . Typically, the installation seam should consist of three layers: an outer vapor-permeable layer, a central heat and noise insulation layer, and an inner vapor barrier layer. Often the outer layer (tape, sealant or plaster) is not done at all or done poorly. Because of this, after a year or two the foam completely loses its insulating and heat-shielding properties and crumbles. If, with all this, there was still a saving in materials, that is, insufficient foaming to the entire depth of the opening with the admission of voids (exactly in the center of the opening), then in winter you will find unpleasant surprises in the form of condensation, mold and drafts due to temperature changes. The inner layer (tape or sealant) is also often not done, which leads to the destruction of the foam from the inside. But it is worth mentioning that the internal seam, unlike the external one, is not always necessary. It is applied only when finishing slopes with wet materials: plaster for exterior use and drywall.

- Careless finishing of slopes . Most often, slopes are installed cut from pieces of material. Provided that the sealant is applied properly, the seams can be reliably protected from moisture. However, the basic technology involves the installation of monolithic slopes without cuts, breaks or cracks, otherwise the appearance of mold and condensation cannot be avoided.

Correct installation of slopes ensures reliable moisture insulation

- Installation of ebb tides . The ebb is not always cut exactly along the width of the opening; there are gaps on the sides that must be plastered or sealed with sealant. If this is not done, moisture will begin to get under the ebb, destroying the installation seam. Often the ebb is simply laid on the opening without gluing soundproofing tape or foaming the space underneath. This way you will know exactly when the rain started and stopped.

- Window sill installation . The process is not so complicated, but very responsible. As with the frame, incorrectly selected pads disrupt the level of the window sill. For these purposes, it is worth choosing high-quality plastic or wooden products. A large step when installing them leads to sagging of the window sill, the formation of gaps, and a violation of the tightness of the structure.

- Incorrect finishing of slopes . If we talk about external slopes (from the street side), then here they can use materials (plaster, sealant) for internal work, which quickly collapse under the influence of moisture, sun, and snow.

If we are talking about internal slopes, then you need to understand which option you chose. When plastering internal slopes, do not forget about preparing the opening (priming, installing reinforcing mesh). If the plaster layer is thick, you should not do everything in one go. When installing plasterboard slopes, you should not use non-moisture resistant material; it can swell or become moldy due to changes in humidity and temperature. Both drywall and plastic panels should be cut perfectly evenly to obtain minimal gaps at the joints, which can be easily covered up. The slopes must be secured to the opening securely to avoid cracks at the joints.

- Insufficient adjustment of window mechanisms . The use of tilt, turn and micro-ventilation is often difficult due to unlubricated or unadjusted mechanisms and defects. The installers must make the adjustments in your presence and show you several times how to use them correctly.

It is very important to check the operation of the mechanisms in the presence of workers

- Failure to press the sash tightly against the frame can lead to blowing in the winter and subsequent formation of condensation or ice. On the contrary, too tight a clamp can lead to failure of the fittings. It is worth paying attention to this when accepting windows.

Making a claim

It is written by hand in two copies.

Let us briefly repeat what should be in this important document:

- the name of the performing company with its exact location address;

- your full name and telephone number to contact you;

- description of the identified defects – briefly and in as much detail as possible;

- there is no need to list all the defects, just one most significant one is enough, which is worth writing about;

- state your requirements;

- set deadlines for fulfilling your claim. Usually it is 10 working days;

Don't forget to indicate the date and sign the papers.

Inadequate surface preparation

The quality of surface preparation is very critical for the correct installation of windows and double-glazed windows. Remains of concrete, stone chips, dust, fragments of sealant left over from a previous installation - all this will prevent the new window from being installed correctly. Garbage will interfere with insulating materials, disrupt the bonds of the materials used, and cause drafts and heat loss during the cold season.

Before installation, the surface must be thoroughly cleaned, primed and dried.

What to do if the claim is not accepted

Your opponents do not want to accept your claim, despite the fact that there is all the evidence of their guilt, including the conclusions of the examination. What should I do, go straight to court?

Take your time, it is better to send your claim by mail, registered mail with a simple notification.

Attention! In this case, the post office will deliver your message directly to the addressee, and will send you a delivery notification indicating the date and time. This will further serve as proof that the addressee has received the claim in the event that it is necessary to go to court.

Going to court

Refusal to fulfill a claim is formalized in the form of a resolution from the person or organization to which it was addressed. If you receive such a refusal, do not be upset. Having the conclusion of an independent expert in your arsenal, you can file a claim in court with complete confidence in victory.

The Consumer Rights Protection Society will again come to the rescue, which will explain and guide you in the right direction as part of a free consultation. Thus, a lawsuit should be drawn up based on a number of rules, which are listed below.

The legislator allows both handwritten and printed forms of the statement of claim. The plaintiff is required to indicate the last name, first name and patronymic of both his and the defendant, who is the head of the company, his and the defendant’s address information, including contact telephone numbers.

If the claim is sent by a legal entity, then the legal and actual addresses of the company, individual entrepreneur, as well as telephone numbers are indicated. It is also necessary to indicate the official representative of the company, his name and contacts.

Where can I file a claim?

The general rules of the courts determine that the claim is filed at the place of presence of the defendant - at the legal address of the company or the actual location of its branch, the address of the representative office or store. By the way, it is recommended to indicate both addresses in the statement of claim, one being designated “for correspondence.”

Important! The issue of the level of the judicial body is determined by the amount of the claim or the price of the claim: if it is up to 50 thousand rubles, then the application is considered by a magistrate, if it exceeds this limit, then by a federal judge - the claim is filed in the district court.

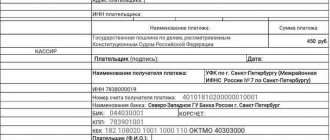

Payment of state duty

Tax Code, namely Art. 333.36 determines the following when calculating the state duty: if the amount of the claim is up to 1 million rubles. no duty is charged. It is advisable to illustrate the calculation of the duty if the amount of the claim is more than a million rubles with a specific example.

So, the calculation is made as follows:

The cost of the claim is 2 million rubles. At the same time, the law establishes a fixed amount of 13,200 rubles; accordingly, 2 million rubles are added to it, and 1 million rubles are subtracted. (since a different calculation procedure is provided for this amount) and is multiplied by 0.5%. As a result, we get the amount of state duty of 17,200 rubles.

Let us give an example of a calculation for a claim amount of 1 million rubles. To the fixed amount of 5200 we add (1 million – 2 million)*1%. =13200 rub. We calculate the amount of the duty: 17200-15200=5000 rubles.

Lack of window sill

It will interfere with the sealing of the joint between the external window sill and the window frame and can lead to water penetrating under the window frame and wetting the wall, and subsequently even to corrosion of the dowels. The sill strip should be slightly narrower than the frame, which will allow the external window sill to be installed under the window frame.